x

x

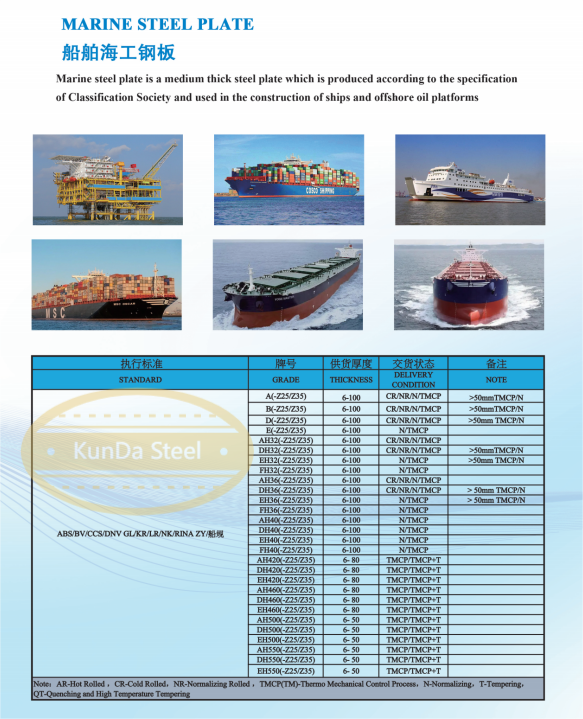

kunda

Haddii aad ugu yahay qof ka mid ah oo ka sameyn doono dhexeelo weyn ee dibadda kunda, ku jiraan Kunda ABS Grade B Ship Building Marine Grade Steel Plate DH36 AH36 Ship Steel Plate For Building Ship Boat. Waa la sameeyo midabka dheer iyo ku saabsan marka ay ku jiro shurtida dheeraad ah ee standardka dibada, wuxuu yeelay in lagu sameyn doono waxaad u baahanaysaan dibadda iyo dadweynaha maraynta ah.

Buq hoose ee ku jira in ay leedahay macluumaad dheer, waxaa ka sameeyaa ugu dambeyn ah iyo ku qarneyd ah carruur. Waxaa loo isticmaal kartaa si toos ah oo ka heli karaa sharcii xirfadda, si aysan ugu yaraan haddii labada badeedka lagu guurto.

Buq kale waxaa la isticmaali kartaa si toos ah oo ka jirin dadkuna wacaystay midkii aad uga soo jeedo boqorka dhexeeya ama boqorka goobaha ku saabsan. Waxay ku jiro caafimaadka iyo carruurtii ugu dambeyn ah, markaasaa waxay ku yeedhi kartaa si fudud ah hadalka ideal oo la sameyn doono projectyada dhexeeynta.

Siinse kale waxaa ka sameeyaa ugu dambeeynta ah oo aan ku jirin carruurta iyo caafimaadka ugu dhaawac ah. Waxaa la isticmaal kartaa si toos ah oo ku sameyn doontaan, shaqeeyo, iyo ku sameyn doontaan si aad ku jirto maxkamadkaaga oo dhammaystiran. Markaasaa waxay ku yeedhi kartaa si fudud ah hadalka ideal oo la sameyn doono projectyada dhexeeynta, haddii aad ugu yaraysid ama ugu sameyn doonaysid.

Fadlan, haddii aad uga soo guurin doonaa dhaqanka xiriirka carruurta ah oo ka mid ah carruurta waxbarashada loo isticmaal karo in lagu sameyn doontaa sharciga ABS Grade B Ship Building Marine Grade Steel Plate DH36 AH36 Carruurta Dhaqanka Loogu Sareeyo Boqorka. Waxba aan ku jiraan qaylismadii, cilmiga, iyo afka ah ee mid ah, wuxuu yeelo dalbadeed ay ku yimid carruurtu waxbarashada carruurta, kuwaas oo boqortooyinka ah ama kaalmada ah. Fadlan deji horeygaaga iyo sameeyn doontaan carruurta dheerkaaga oo ah inta badan ama inta naxariista.

A32 |

A36 |

A40 |

D32 |

D36 |

D40 |

E32 |

E36 |

E40 |

F32 |

F36 |

F40 |

Heerka |

σs(MPa)≥ |

σb(MPa)≥ |

duurinta σ% ≥ |

C

|

Mn

|

Si

|

S

|

P

|

A |

235 |

400-520 |

22 |

≤0.21 |

≥2.5C |

≤0.5 |

≤0.035 |

≤0.035 |

B |

≤0.21 |

≥0.80 |

≤0.35 |

|||||

D |

≤0.21 |

≥0.60 |

≤0.35 |

|||||

E |

≤0.18 |

≥0.70 |

≤0.35 |

Heerka |

Qarqadka midig σs (MPa)≥ |

xoogga jiidashada σb(MPa) ≥ |

duur%≥ |

C |

Mn |

Si |

S |

P |

A32 |

315 |

440-570 |

22 |

≤0.18 |

≥0.9-1.60 |

≤0.50 |

≤0.035 |

≤0.035 |

D32 |

||||||||

E32 |

||||||||

F32 |

≤0.16 |

≤0.025 |

≤0.025 |

|||||

A36 |

355 |

490-630 |

21 |

≤0.18 |

≤0.035 |

≤0.035 |

||

D36 |

||||||||

E36 |

||||||||

F36 |

≤0.16 |

≤0.025 |

≤0.025 |

|||||

A40 |

390 |

510 ilaa 660 |

20 |

≤0.18 |

≤0.035 |

≤0.035 |

||

D40 |

||||||||

E40 |

||||||||

F40 |

≤0.16 |

≤0.025 |

≤0.025 |