×

×

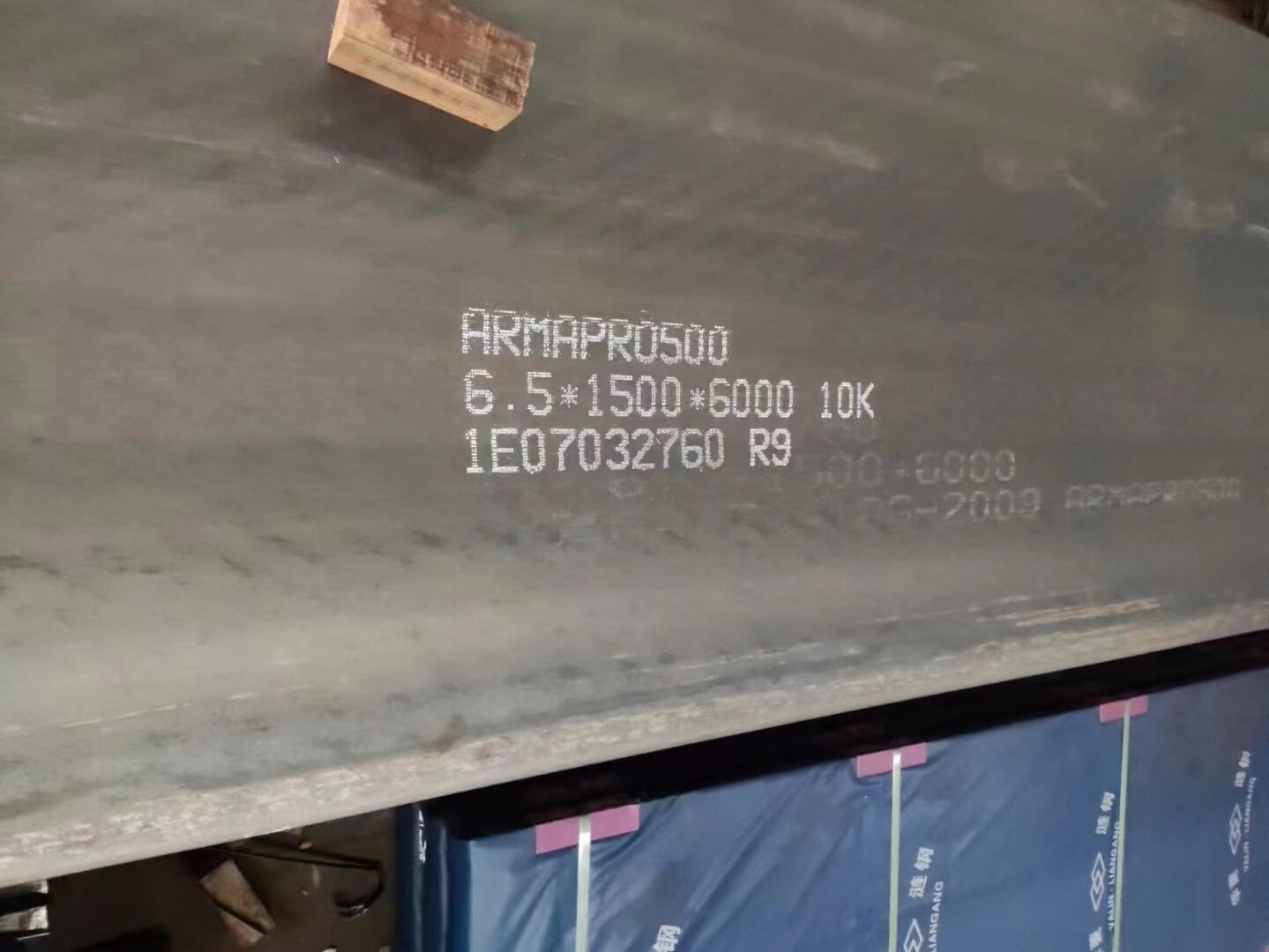

Kunda NM400 Wear and Abrasion Resistant Steel Plate may be the solution that is applications that are ideal need high-strength, durability, and opposition to abrasion and wear. This steel plate is constructed of typical metals like iron, carbon, and manganese, it is specifically built to withstand harsh environments and use that is hefty.

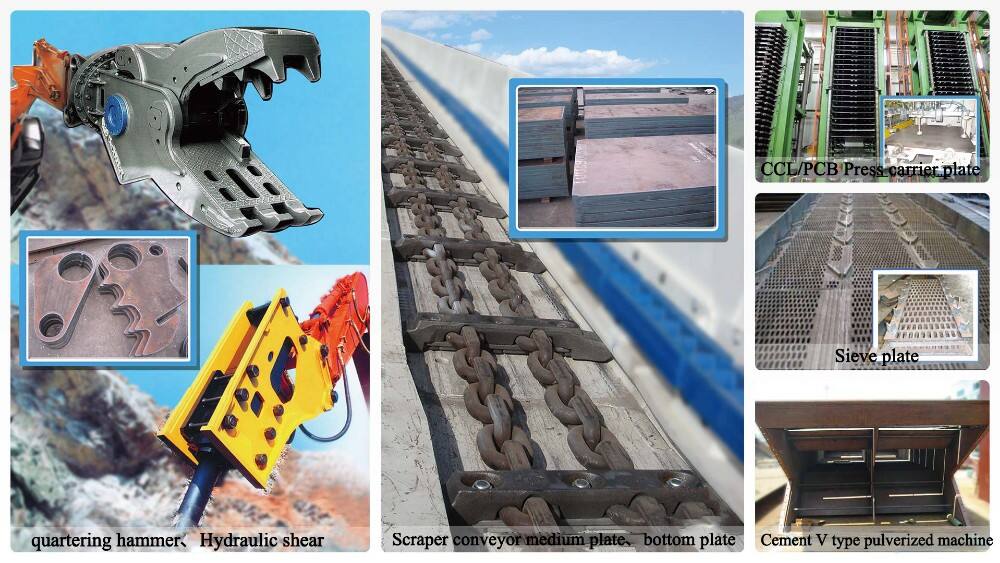

Exactly what sets Kunda NM400 Wear and Abrasion Resistant Steel Plate apart is its energy this is certainly plus that is superior. It would likely withstand impact this is certainly high pressure without cracking or breaking, making it ideal for applications in industrial and manufacturing settings where heavy equipment is employed. Its abrasion-resistant properties also ensure it is a variety this is certainly mining that is popular construction, and transportation industries.

This metal plate is wonderful for areas that endure constant wear and tear, such as for example conveyor belts, chutes, hoppers, and buckets. It really is built to resist the impact of abrasives, such as for example sand, gravel, or minerals, which could cause damage this is certainly metals that are mate.

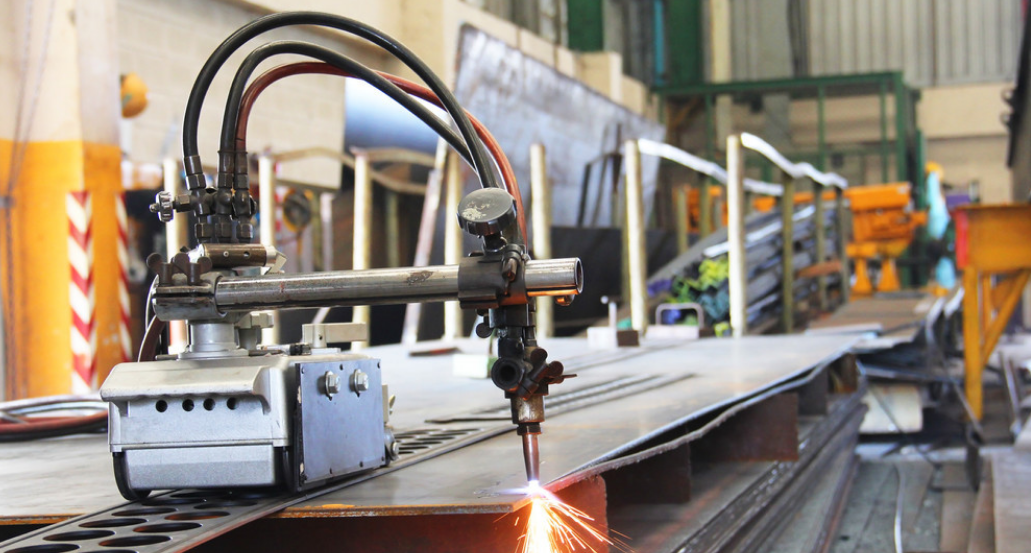

Kunda NM400 Wear and Abrasion Resistant Steel Plate can be very easy also to utilize. It may be cut, bent and welded to suit shapes being different sizes, which makes it customizable for all applications. Additionally, it really is corrosion-resistant, rendering it a choice this is certainly dependable outdoor and marine applications.

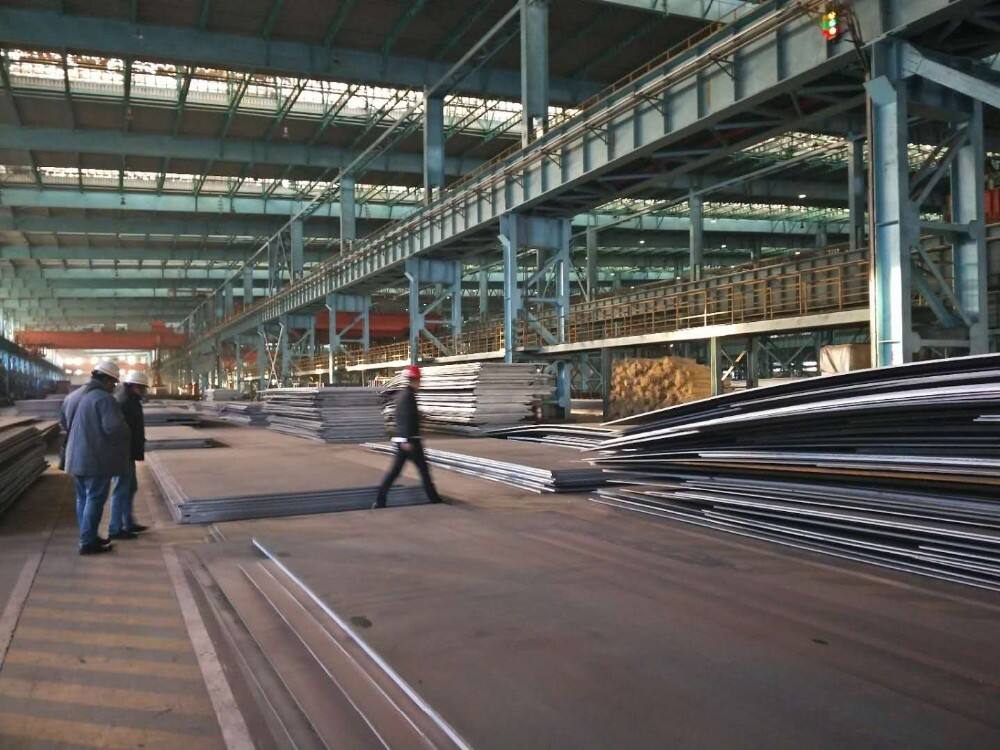

The item brand, Kunda, is a title this is certainly trusted the metal industry. It's been providing metal that is high-quality for more than 2 full decades and contains now a track record of excellence and dependability. Kunda NM400 Wear and Abrasion Resistant Steel Plate isn't any various, supplying strength this is certainly superior durability for your application needs.

Product Name |

Wholesale Price 6mm 8mm NM400 Wear Resistant Steel Plate Abrasion Resistant Plate For Cement Plant wear steel plate |

GB |

NM300,NM360,NM400,NM450,NM500 |

SS |

HARDOX400、HARDOX450、HARDOX500、HARDOX600 |

DIN |

XAR400、XAR450、XAR500、XAR600、Dillidur400、Dillidur500 |

NBN |

QUARD400、QUARD450、QUARD500 |

NF |

FORA400、FORA500、Creusabro4800、Creusabro8000 |

JIS |

JFE-EH360、 JFE-EH400、JFE-EH500、WEL-HARD400、WEL-HARD500 |

SFS |

RAEX400、RAEX450、RAEX500 |

Capacity |

4,500 tons/Month |

Steel/Grade |

C |

Si |

Mn |

P |

S |

AL |

Cr+Ni+Mo |

Nb+V+Ti |

|

NM360/AR360 |

0.10-0.30 |

0.20-0.40 |

1.00-2.00 |

≤0.015 |

≤0.003 |

≥0.20 |

Trace Amount |

||

NM400/AR400 |

0.10-0.40 |

0.20-0.40 |

1.00-2.00 |

≤0.015 |

≤0.003 |

≥0.20 |

|||

NM450/AR450 |

0.10-0.40 |

0.20-0.40 |

1.00-2.00 |

≤0.015 |

≤0.003 |

≥0.20 |

|||

NM500/AR500 |

0.10-0.40 |

0.20-0.45 |

1.00-2.00 |

≤0.015 |

≤0.003 |

≥0.20 |

|||

NM550/AR550 |

0.10-0.50 |

0.20-0.45 |

1.00-1.50 |

≤0.015 |

≤0.003 |

≥0.20 |

|||

NM600/AR600 |

0.10-0.50 |

0.20-0.45 |

1.00-1.50 |

≤0.015 |

≤0.003 |

≥0.20 |

Mechanical property |

||||||||

Grade |

Thickness (mm) |

tensile strength(MPa) |

Elongation A(%) |

Surface Brinell hardness(HBW) |

||||

NM300 |

≤80 |

≥1000 |

≥14 |

270-330 |

||||

NM360 |

≤80 |

≥1100 |

≥12 |

330-390 |

||||

NM400 |

≤80 |

≥1200 |

≥10 |

370-430 |

||||

NM450 |

≤80 |

≥1250 |

≥7 |

420-480 |

||||

NM500 |

≤70 |

- |

- |

≥470 |

||||

Shandong Kunda NM400 NM 500 wear resistant steel plate price

We are professional wear-resistant steel suppliers,wear resistant steel plate is committed to domestic and imported steel NM250, NM360, NM400, NM450, NM500, NM550, NM600 bulk sales, warehouse, cutting and distribution. In the meantime, in order to open the high-end user market, XC-HD400/450/500 series with good wear resistant, welding and cold machining performance,.

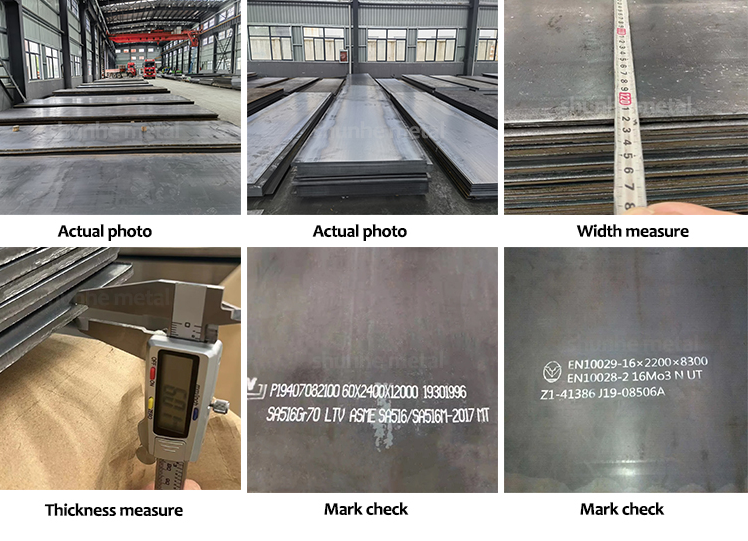

● Factory audit & assessment

● Packing inspection / marking verification.

● Pre-Shipment Inspection.

● After-sales services.

● Sourcing (Resistance Steel, Wear-Resistant Steel, and Weathering Resistant Steel, etc.,Tearing Corten Steel, Low Alloy Steel, Ship-Building Steel, Boiler and Pressure Vessel Steel, High Strength Steel, Bridge Steel, Anti-Seismic Steel, Z15/Z25/Z35 Carbon Steel, Stainless Steel.

● Products inspection of Straightness,Flatness, Inherent defects, Dimensions, Welding Quality, Finish/Cleanliness, material analyzing and Mechanical properties testing; MTR.