Kunda

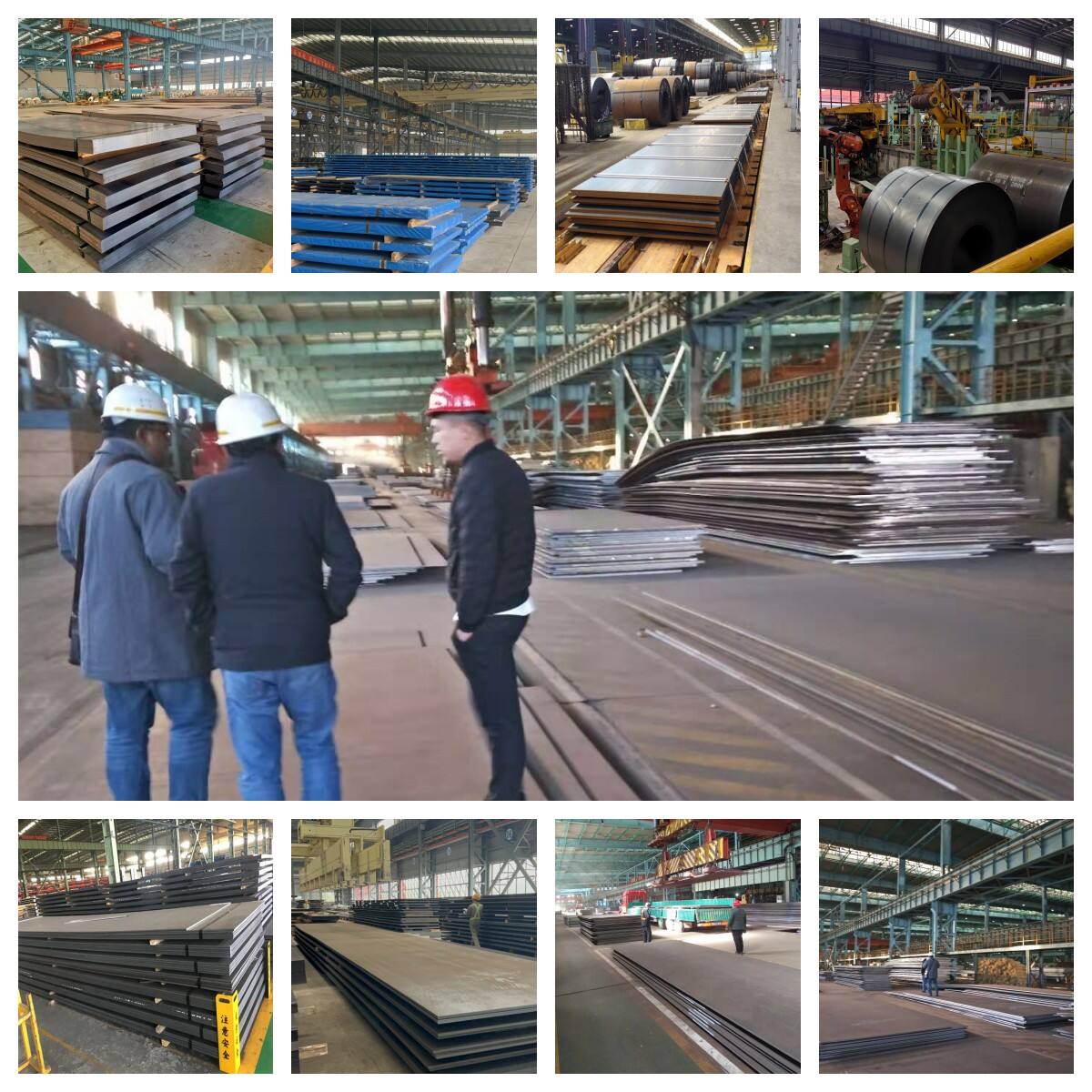

High-Strength wear that is non-Magnetic Steel Plate is a top-quality item that's created to provide durable in many different commercial applications. This plate is constructed of high-strength materials are engineered to withstand perhaps the most demanding conditions, rendering it an option is certainly very good companies such as for example mining, construction, and production.

One of many standout top features of this metal dish is its opposition that superb to and tear. It's specifically made become highly resistant to abrasion, impact, as well as other kinds of damage, meaning it could remain true to make use of is heavy showing any signs and symptoms of wear. This can allow it to be a choice is ideal applications where wear and tear are a concern that is significant such as conveyor systems, equipment elements, and drilling equipment.

Another advantage that is key of High-Strength wear is non-Magnetic Steel Plate is its non-magnetic properties. This makes it an option is fantastic applications where magnetic disturbance could be an issue, such as particular forms of manufacturing and research is medical. Additionally, this plate is extremely resistant to corrosion, rendering it well suited for used in harsh surroundings where exposure to dampness or other materials which are corrosive a problem.

This metal plate is surprisingly lightweight, making it an easy task to manage and transport despite its durability and strength. Additionally it is extremely customizable, by having an array of thicknesses and proportions accessible to match requirements that can easily be different. This can make it and choice is certainly great a myriad of applications, from heavy-duty equipment that is industrial lightweight consumer products.

Product Name |

Hot Rolled Wear Resistant Steel Ar400/Nm400/Ar500/Nm500/Ar600/Nm600 Wear Plate for Mining Machinery |

Specification |

Width:500-2500mmLength:1000-6000mm

Thickness:6mm---40mm |

Material |

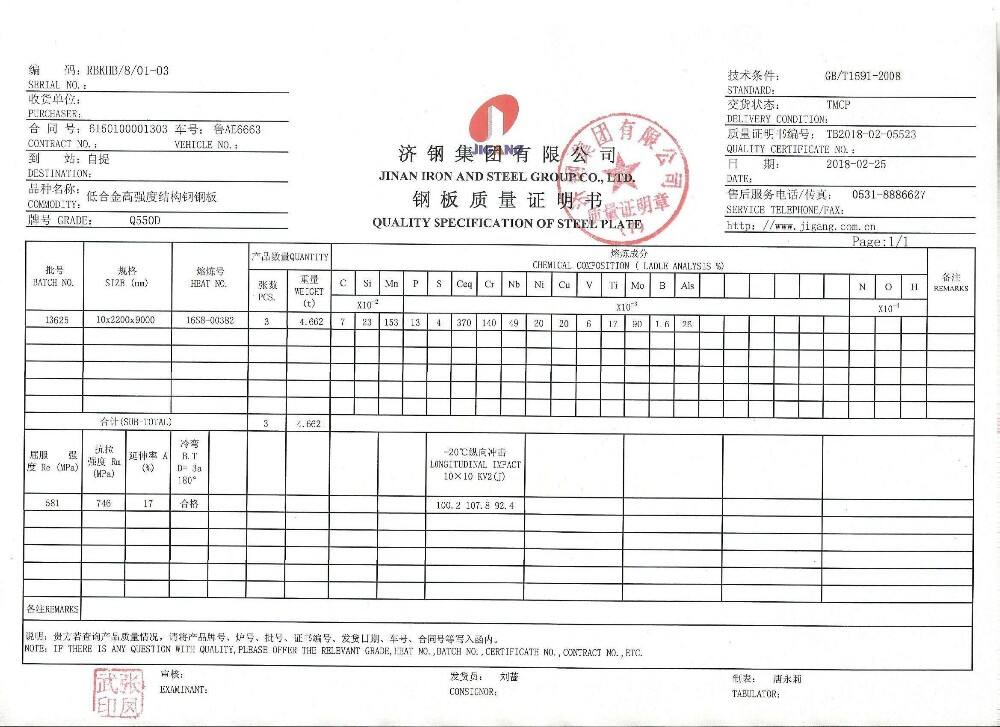

NM360 NM400 NM450 NM500 NM550JFE-EH360 JFE-EH400 JFE-EH500

Xar300 Xar400 Xar450 Xar500 Xar600

RAEX400 RAEX450 RAEX500

FORA400 FORA500 |

Package |

Standard seaworthy package(wooden boxes package, and other package or as your requirement) |

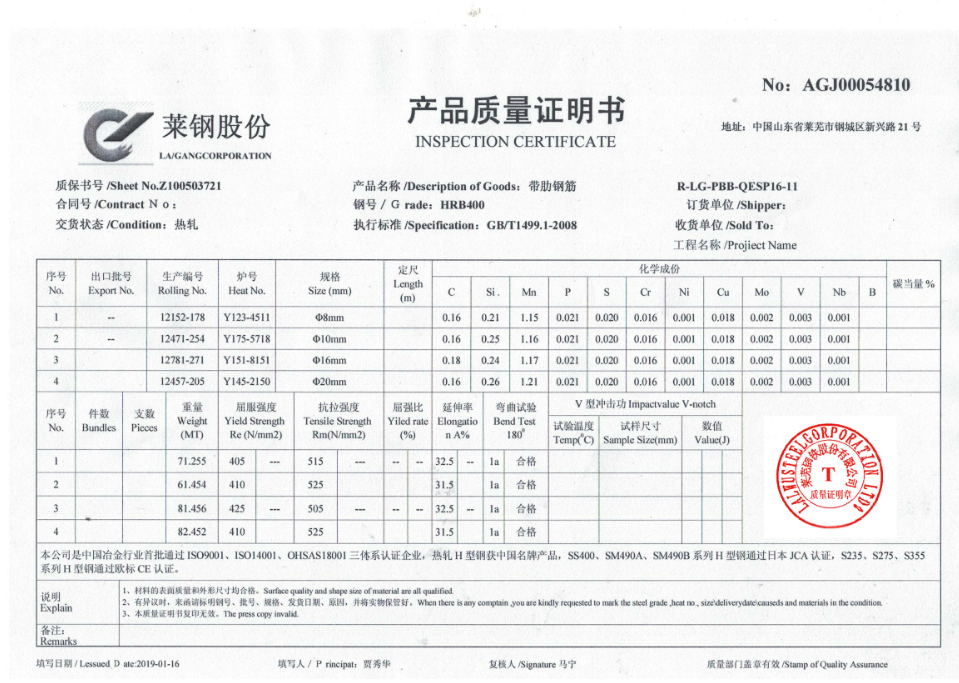

Standard |

JIS,AISI,ASTM,DIN,EN,GB |

Delivery Time |

3-10 days after receiving the deposit |

Payment Terms |

30% TT in advance 70% balance before delivery |

Application |

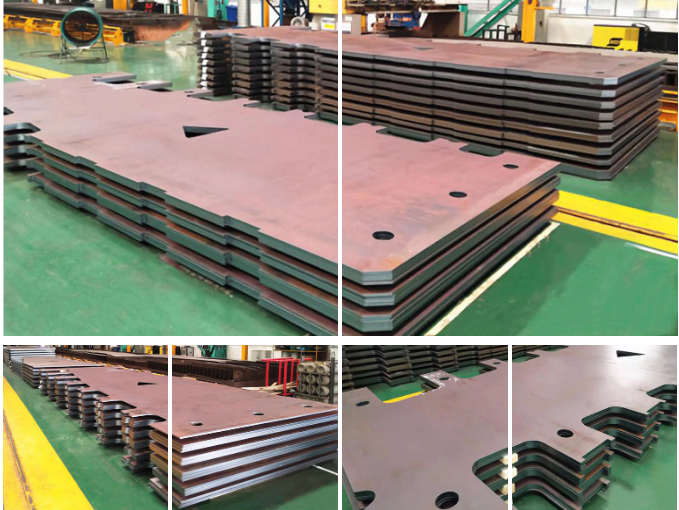

Widely used in construction machinery, mining machinery, coal mining machinery, environmental protection machinery, metallurgical machinery and other parts, Excavator, loader, bulldozer bucket plate, side blade plate, crusher line etc. |

Characteristics of wear-resistant plates

The characteristics of wear-resistant plates are that wear-resistant plates have high hardness and wear resistance, and can resist the influence of factors such as wear, impact, and high temperature. Its hardness can reach 400-600HBW or even higher. At the same time, wear-resistant plates also have a certain degree of toughness and weldability, making them easy to process and install. Its surface is usually treated by sandblasting or coating to increase its wear resistance.

Application fields and maintenance characteristics of wear-resistant plates

Wear resistant plates are widely used in many industrial fields, including mining, metallurgy, construction, chemical industry, etc. They can be used to manufacture the lining of conveyor systems, such as conveyor drums, hoppers, storage silos, etc; It can also be used to manufacture lining for ore processing equipment, such as crushers, screening machines, etc; In addition, wear-resistant plates can also be used for concrete mixers, grinding machines, coal mining equipment, etc.

When installing wear-resistant plates, they need to be fixed on the internal surface of the equipment, usually using bolts or welding for fixation. In terms of maintenance, regularly check the wear of the wear-resistant plate and replace the severely worn parts in a timely manner to ensure the normal operation of the equipment.

Market prospects of wear-resistant plates

With the advancement of industrialization and the increasing demand for equipment lifespan, the wear-resistant plate market will continue to grow. Especially in industries such as mining, metallurgy, and construction, the demand for wear-resistant plates will increase. Meanwhile, with the continuous development of technology, the research and application of new wear-resistant plates will also become an important trend in the market.

*What is your paying terms?

Our usual paying terms are 30%TT as deposit and balance paid after seeing copy of bill of loading. For clients cooperated for more than one year, we accept 20% prepay. Beside we do business also under D/P and LC terms.

*How long is your delivery time?

For the goods we have in stocks, we deliver the goods within 5days. If it is a production order with volume not above 200tons, the delivery time will usually be within 20days after sealing contract. And the delivery time shall be slightly longer for order volume above 200tons.

*Can you do partial shipment?

We will follow client request to do partial shipment or not. Partial shipment is not a problem for us.

*What is your Minimum Order Quantity?

For goods in stocks we supply starting with one piece. Shall it is a production order, the MOQ is 3tons. Please be noted price based on MOQ will be slight higher than FCL condition due to higher unit cost.

*Before cooperation we want a sample for inspecting of quality, is that okay?

We can provide a free sample for you shall sample value not above 30USD, you only need to pay the express charge. For a sample valued more than 30USD, the express charge and just one half of sample value is on the account of you, and we afford the other half.

*What is the mode of transportation?

Ocean freight is the most important shipping way, and we choose the ship line based on soonest and earliest shipping time, rather than cheaper cost; or we follow clients' instruction if there is one. Also railways will be chosen by us when it is more convenient. For samples and papers, the transportation will be by air.

×

×