×

×

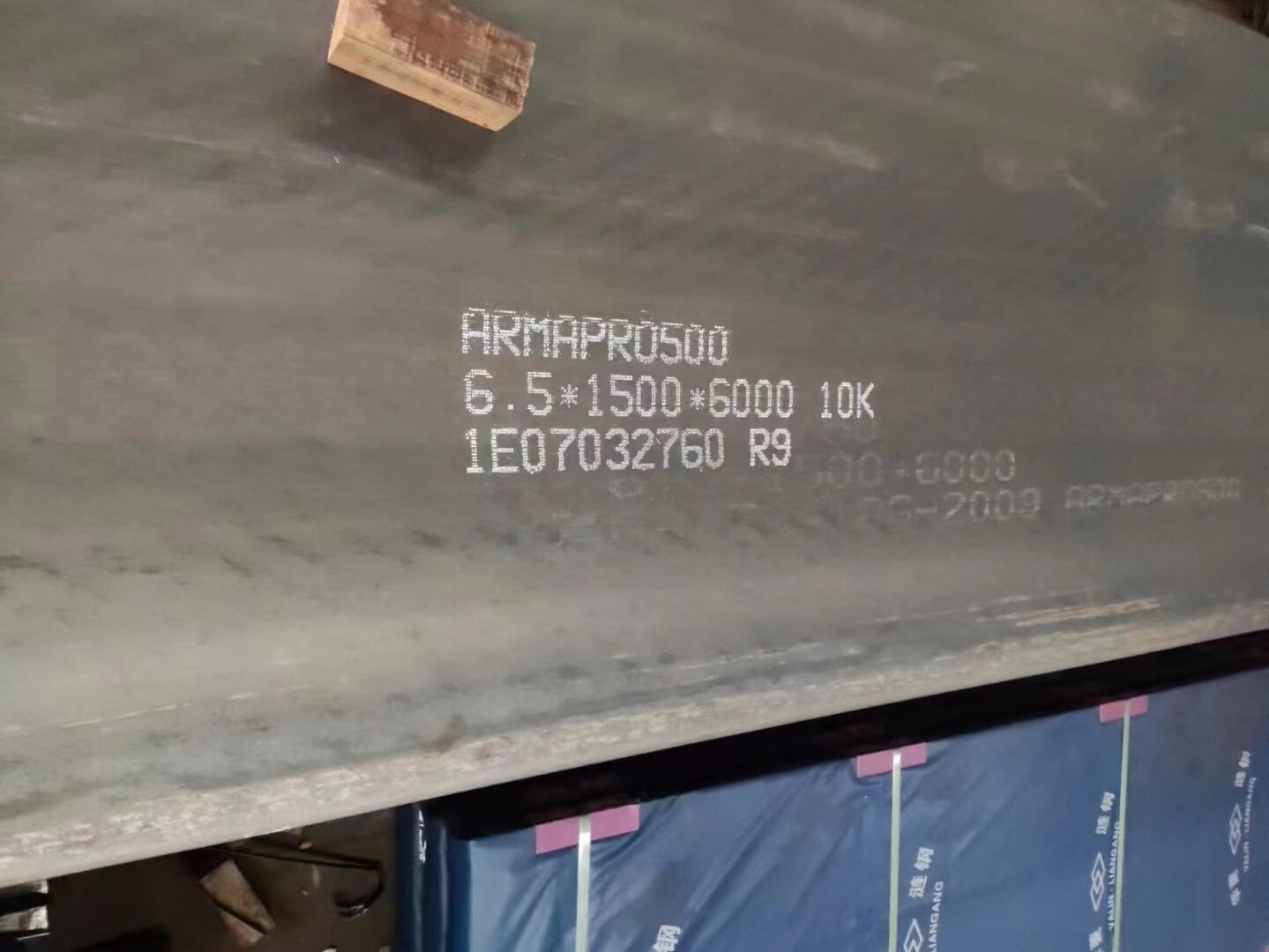

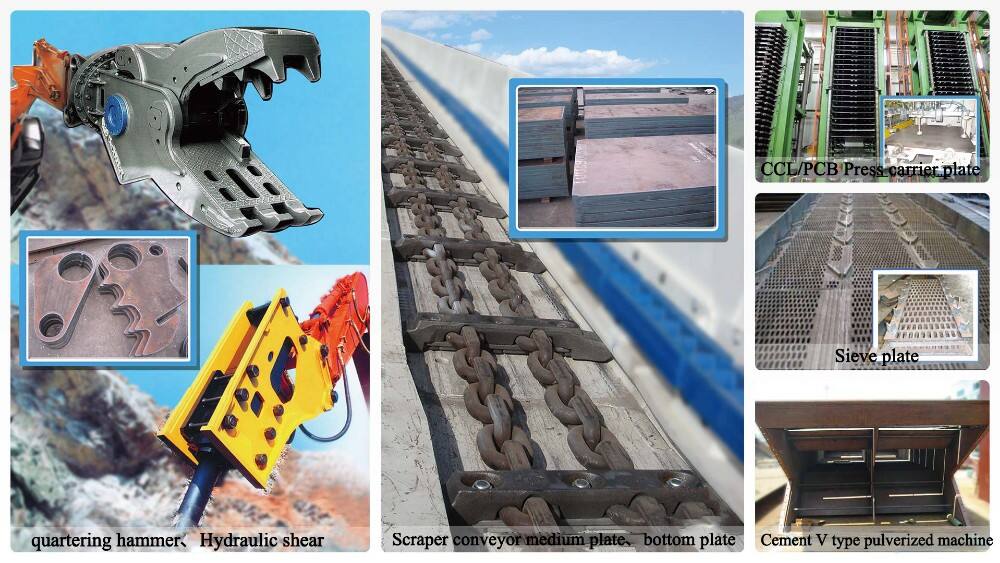

Kunda’s NM500 and NM550 Scratch Wear Resistant Steel Plates are crucial items for industries that are looking for extreme durability and durability inside their gear. Designed to withstand harsh conditions and wear this is certainly heavy these steel plates can be utilized in many different applications including mining, construction, farming, and transportation.

Made of top-notch materials, Kunda’s NM500 and NM550 Scratch Wear Resistant metal Plates are especially engineered to resist scratches, abrasions, and impact damage. This material established fact because of its unique blend of toughness and hardness, making this an option that is ideal environments where gear is the subject of high levels of wear and tear.

The most impressive features of the NM500 and NM550 Scratch Wear Resistant Steel Plates is the energy this is certainly exceptional plus. These dishes can withstand perhaps the many conditions which are extreme maintain their form and function without deformation or failure. Additionally, the plates have impact this is certainly high that will help one to prevent damage and prolong the lifespan of equipment.

The NM500 and NM550 Scratch Wear Resistant Steel Plates also provide excellent corrosion opposition with their outstanding durability. This is why them suitable for used in harsh, corrosive surroundings where other materials may breakdown or deteriorate into the run that is long.

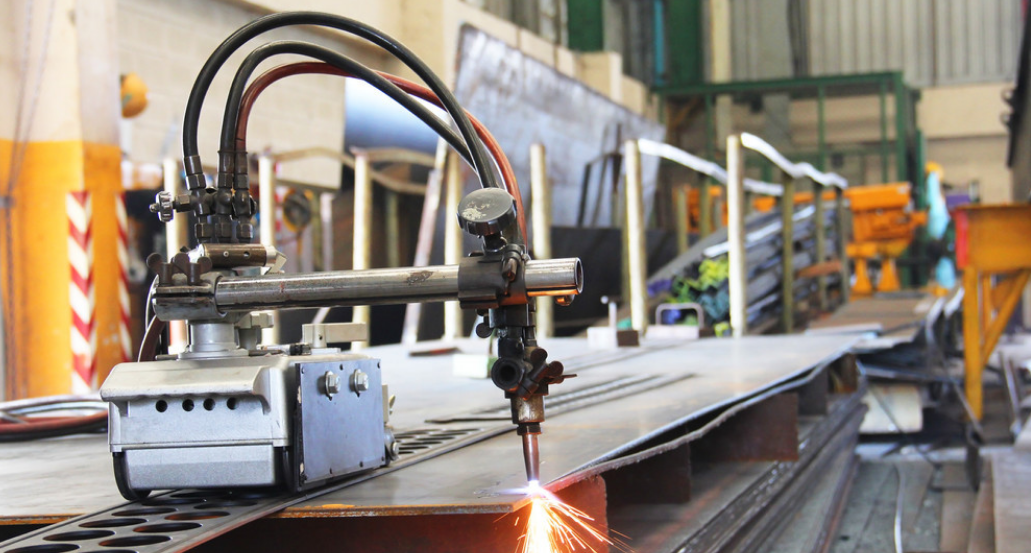

Another advantage this is certainly key of metal dishes is the simplicity of use. They can be cut, shaped, and welded to match many applications that are different and therefore could be individualized to match design that is particular. Also, the laundry are really easy to keep and certainly will be washed using cleaning that is standard and methods.

Product Name |

Scratch Resistant 10mm 20mm 30mm Wear Resistant Steel Plate NM500 NM550 wear resistant plate |

GB |

NM300,NM360,NM400,NM450,NM500 |

SS |

HARDOX400、HARDOX450、HARDOX500、HARDOX600 |

DIN |

XAR400、XAR450、XAR500、XAR600、Dillidur400、Dillidur500 |

NBN |

QUARD400、QUARD450、QUARD500 |

NF |

FORA400、FORA500、Creusabro4800、Creusabro8000 |

JIS |

JFE-EH360、 JFE-EH400、JFE-EH500、WEL-HARD400、WEL-HARD500 |

SFS |

RAEX400、RAEX450、RAEX500 |

Capacity |

4,500 tons/Month |

Steel/Grade |

C |

Si |

Mn |

P |

S |

AL |

Cr+Ni+Mo |

Nb+V+Ti |

|

NM360/AR360 |

0.10-0.30 |

0.20-0.40 |

1.00-2.00 |

≤0.015 |

≤0.003 |

≥0.20 |

Trace Amount |

||

NM400/AR400 |

0.10-0.40 |

0.20-0.40 |

1.00-2.00 |

≤0.015 |

≤0.003 |

≥0.20 |

|||

NM450/AR450 |

0.10-0.40 |

0.20-0.40 |

1.00-2.00 |

≤0.015 |

≤0.003 |

≥0.20 |

|||

NM500/AR500 |

0.10-0.40 |

0.20-0.45 |

1.00-2.00 |

≤0.015 |

≤0.003 |

≥0.20 |

|||

NM550/AR550 |

0.10-0.50 |

0.20-0.45 |

1.00-1.50 |

≤0.015 |

≤0.003 |

≥0.20 |

|||

NM600/AR600 |

0.10-0.50 |

0.20-0.45 |

1.00-1.50 |

≤0.015 |

≤0.003 |

≥0.20 |

Mechanical property |

||||||||

Grade |

Thickness (mm) |

tensile strength(MPa) |

Elongation A(%) |

Surface Brinell hardness(HBW) |

||||

NM300 |

≤80 |

≥1000 |

≥14 |

270-330 |

||||

NM360 |

≤80 |

≥1100 |

≥12 |

330-390 |

||||

NM400 |

≤80 |

≥1200 |

≥10 |

370-430 |

||||

NM450 |

≤80 |

≥1250 |

≥7 |

420-480 |

||||

NM500 |

≤70 |

- |

- |

≥470 |

||||

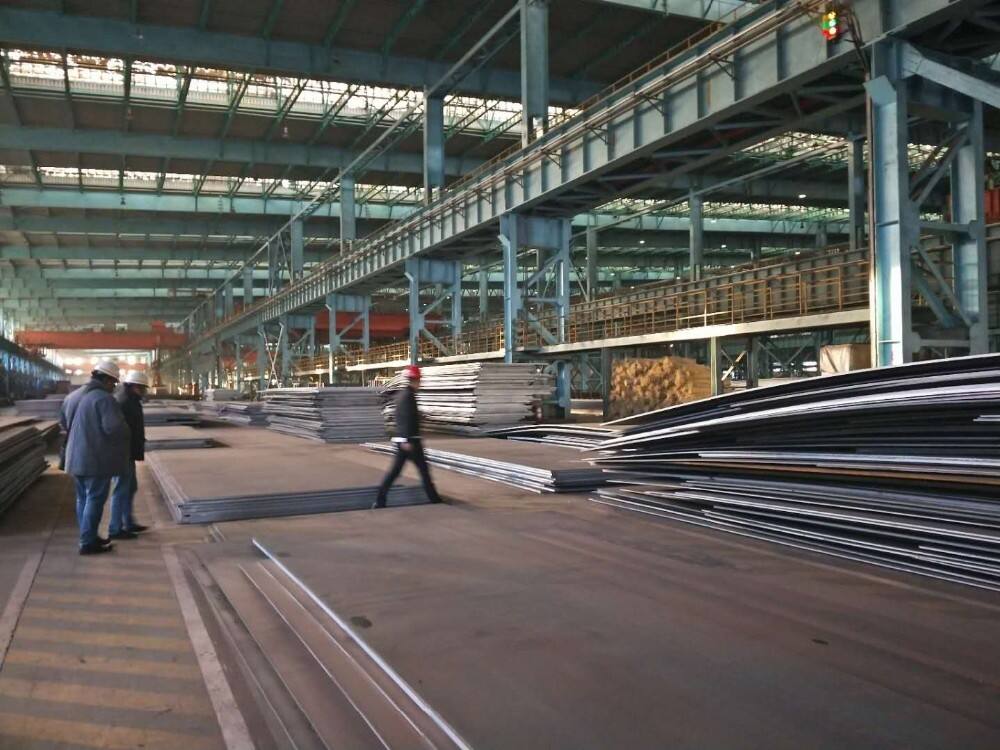

Shandong Kunda NM400 NM 500 wear resistant steel plate price

We are professional wear-resistant steel suppliers,wear resistant steel plate is committed to domestic and imported steel NM250, NM360, NM400, NM450, NM500, NM550, NM600 bulk sales, warehouse, cutting and distribution. In the meantime, in order to open the high-end user market, XC-HD400/450/500 series with good wear resistant, welding and cold machining performance,.

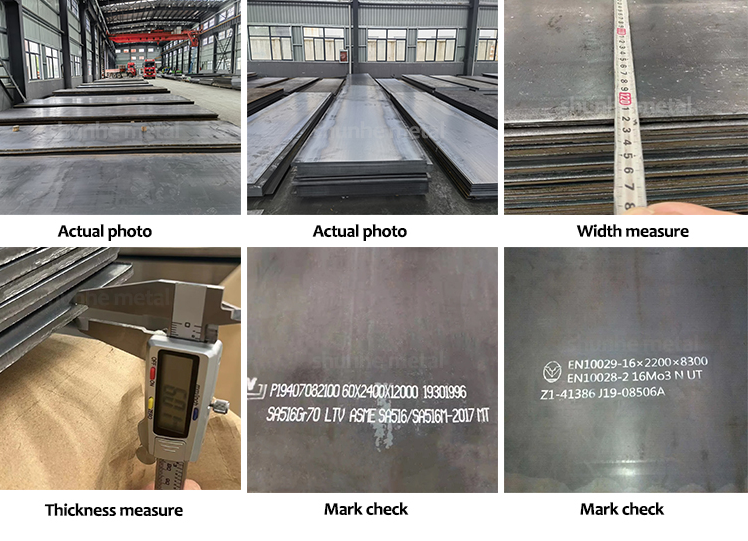

● Factory audit & assessment

● Packing inspection / marking verification.

● Pre-Shipment Inspection.

● After-sales services.

● Sourcing (Resistance Steel, Wear-Resistant Steel, and Weathering Resistant Steel, etc.,Tearing Corten Steel, Low Alloy Steel, Ship-Building Steel, Boiler and Pressure Vessel Steel, High Strength Steel, Bridge Steel, Anti-Seismic Steel, Z15/Z25/Z35 Carbon Steel, Stainless Steel.

● Products inspection of Straightness,Flatness, Inherent defects, Dimensions, Welding Quality, Finish/Cleanliness, material analyzing and Mechanical properties testing; MTR.