×

×

The Ar500 Ar400 Wear Resistant Steel Plate is actually a item this is certainly top-notch by Kunda, a dependable brand within the steel industry. This plate is specifically made to withstand high levels of wear and tear, which makes it perfect for found in industrial and applications that are mining.

The plate is made of a high-strength alloy giving you with security this is certainly superior abrasion, effect, and corrosion. This means the plate is able to withstand the harshest surroundings and continue maintaining its integrity that is structural over. Furthermore, the dish's unique chemical and properties that are technical it very resistant to put up and tear, and can withstand perhaps the many tasks which are heavy-duty.

What sets the Ar500 Ar400 Wear Resistant Steel Plate apart from other items available on the market is its exceptional durability. The plate is constructed technology that is using is advanced top-quality materials, making certain this has a long lifespan and certainly will withstand hefty use without losing its effectiveness. Which means that users can be determined by this system to provide steadfast protection in even the toughest of working conditions.

Thanks to its wear that is resistance that is superior Ar500 Ar400 Wear Resistant Steel Plate is very versatile and that can be utilized in a multitude of applications. Its widely utilized in the construction of mining gear, commercial machinery, vehicle beds, as well as bulletproof vests. Additionally it is used to improve the lifespan of existing equipment by reinforcing areas that are susceptible minimizing the dependence on frequent repairs or replacements.

An additional benefit that is key of product is its simplicity. The dish is made having a thickness that is consistent smooth area, which makes it a facile task to work with and install. What this means is users can quickly and simply integrate the dish to their equipment that is current it be as being a shield that is protective a strengthening system.

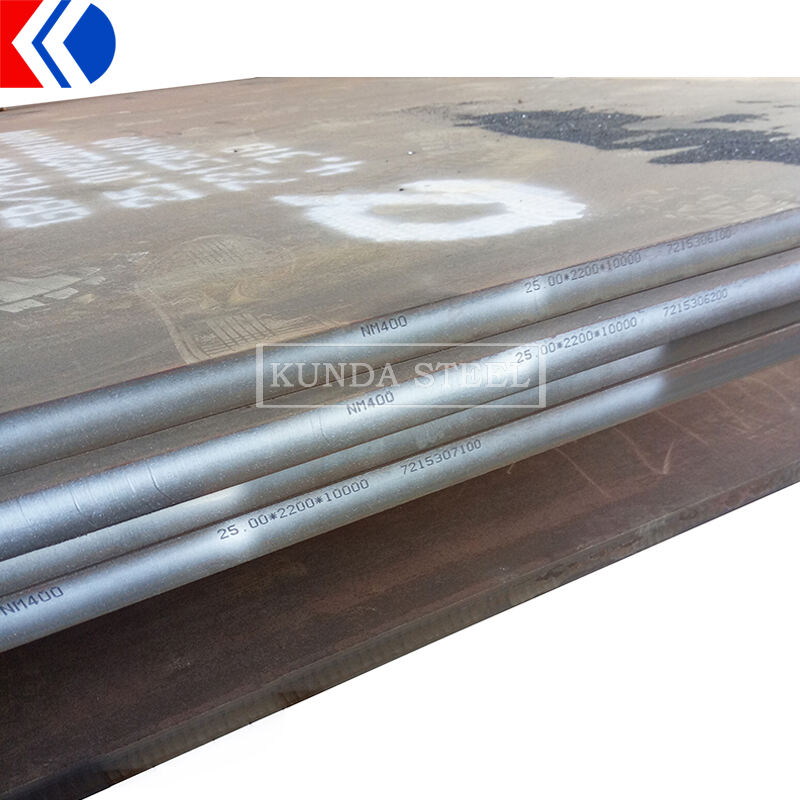

surface treatment |

according to your request |

Materials |

NM450L,NM450A,NM600,NM400,NM400L,NM400A,NM500A,NM500,NM360L,NM360,NM550,NM450 NR360,NR400,MITTA 400F,MITTA 450F,MITTA 500F Xar400,Xar450,Xar500,Xar550,Xar600 SB-40,SB-45,SB-50 QUARD400、QUARD450、QUARD500FORA400、FORA500、Creusabro4800、Creusabro8000 Bisplate500、Bisplate400、Bisplate450 Mn13、B-HARD360、 B-HARD400、 B-HARD450、 B-HARD500 WNM360、WNM400、WNM450、WNM500 RAEX400、RAEX450、RAEX500 ABREX400、ABREX450、ABREX500、ABREX600 High-Mn wear resistant steel plate ZGMn13-1、ZGMn13-2、ZGMn13-3、ZGMn13-4、ZGMn13-5 ASTM-A(UNS-J91109)、ASTM-B-1(UNS-J91119)、ASTM-B-2(UNS-J91129)、ASTM-B-3(UNS-J91139)、ASTM-B-4(UNS-J91149)、ASTM-C(UNS-J91309) ASTM-D(UNS-J91459)、ASTM-E-1(UNS-J91249),ASTM-E-2(UNS-J91339) ASTM-F SCMnH1、SCMnH2、SCMnH3、SCMnH11、SCMnH21 110Г13П、110Г13X2BPП、110Г13ФTП、130Г14、XMФAП、120Г10ФП GX120MnMo7-1、GX110MnMo13-1、GX120Mn13、GX120MnCr132、GX120MnNi13-3、GX120Mn17、GX90MnMo14、GX120MnCr17-2 |

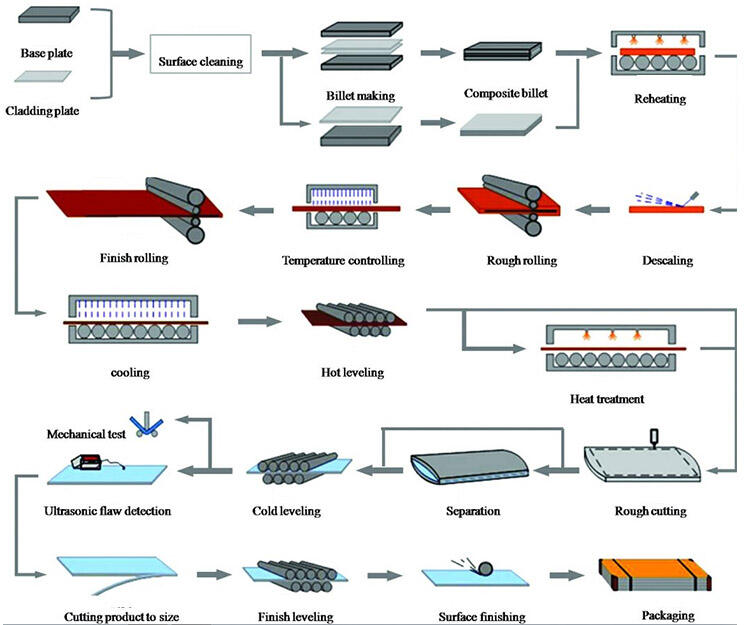

Processing craft |

Quenching and tempering |

Inspection |

ISO,BV,SGS,MTC |