Tungsten carbide wear plates are highly resistant to bending and cutting, making them a perfect option for heavy drudgery. Among others, these plates are known to last in the tough environments and abrasion wear potential that makes them truly resistance to corrosion which is their maximum usage giving a way for use in chemical processing areas or even food production arenas. They are also low in maintenance, easy to clean and last long enough which further reduce the cost of replacements drastically.

Improving Tungsten Carbide Wear Plate Manufacturing

The process of manufacturing tungsten carbide wear plates has been improved upon in recent years, to a great extent. The support of new technologies and equipment made processing units design wear plates section with high precise, quality, efficiency. Additionally, it can make complex shapes that are specific to cater for the desired need of different sectors and hence lends flexibility in application.

With this in mind, people who value safety over anything else often choose to use tungsten carbide wear plates.

The protection of humans working with tungsten carbide wear plates is a major concern to all manufacturers. These plates are quite dangerous to handle and use, so it requires strict safety measures be put in place beforehand otherwise you might end up getting yourself injured or cause damage. When handling wear plates, operators are encouraged to use protective equipment including gloves, goggles and respirators. And besides...being trained on proper storage, transport and application of the plates is crucial in avoiding mishaps and costly equipment failures.

Dosharp carbide wear plates using tips

Using Tungsten carbide wear plates: the process behind it is easy and relatively self-explanatory. They can be attached to a number of different surface with glues, nuts and bolts or even welding techniques. The wear plates must be properly fixed and aligned on the surface to protect. The protection of the airframe during storage is quite extensive and will keep your equipment looking great under almost any cover.

Highlighting Quality When It Comes To Tungsten Carbide Wear Plates

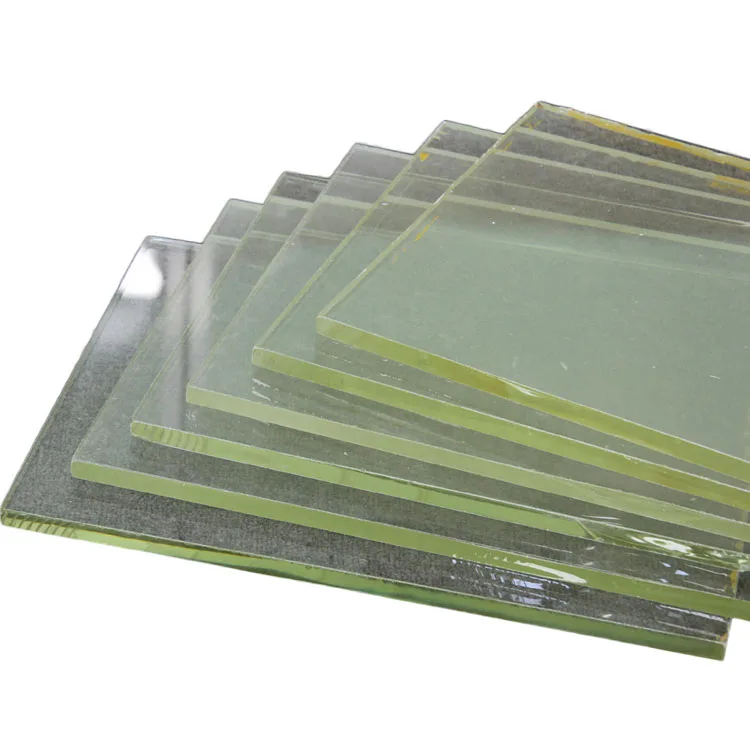

The quality of tungsten carbide wear plates directly affects the value that you will derive from your investment. Quality wear plates are made of best in classmaterials and follow strict manufacturing specifications while being quality checked and tested to ensure top notch performance. This does not mean you should accept unsigned documents, a good manufacturer will provide detailed specifications and certifications demonstrating that the plates are fabricated to meet industry criteria as well as your requirements.

Various Usages of Tungsten Carbide Wear Plates

This is thanks to the broad range of applications in industries such as mining, construction and recycling where tungsten carbide wear plates are widely used. They are used to protect equipment and promote better performance of operation. From farming machinery to plastic injection molding, tungsten carbide wear parts have drastically boosted efficiency whether on the farm or at a plant.

Importance of Tungsten carbide long for Life Plates

Choosing the perfect tungsten carbide wear plate manufacturer requires taking into account several aspects like advantages, production technology, safety precautions usage recommendations quality norms and of course application flexibility. A good manufacturer will provide customized solutions and meet your specific needs across material science, design conceptualisation and ideation to final fabrication & machining. The reputable manufacturer is sourcing top quality products that are guaranteed to remain effective for your investment.